- #TROCHOIDAL MILLING PROGRAMMING UG NX DEMO HOW TO#

- #TROCHOIDAL MILLING PROGRAMMING UG NX DEMO FULL#

- #TROCHOIDAL MILLING PROGRAMMING UG NX DEMO FREE#

Rest Machining This intelligent cycle can automatically remove areas of residual material left behind by the tool size and depths of cut. The Waveform tool path increases tool life and is also kinder to the machine tool. Consistent tool loads generated from the waveform tool path offers the user the opportunity to rethink speeds, feeds and depths of cut. Wave form toolpath has been developed to remove tool load spikes and maintain and even chip thickness and generating a fluid tool path throughout the machinable elements using a flowing motion.

TRADITIONAL tool paths have to run slower feeds and speeds due to the variable widths of cut condition when encountering corners and material entry. Waveform Roughing Waveform cycle is superior to the traditional roughing cycle where machinable geometry is offset inward or outward by % step over.

#TROCHOIDAL MILLING PROGRAMMING UG NX DEMO FULL#

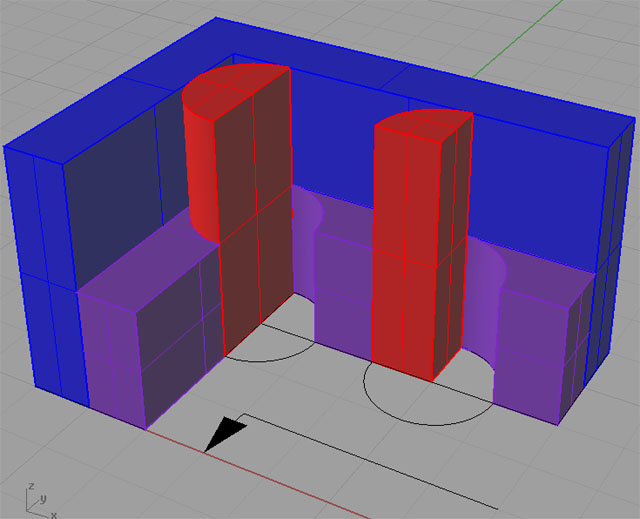

Roughing EDGECAM applies the most efficient approach move for each region of the model utilizing waveform cycle and trochoidal cutter paths to avoid full width cuts, automatically adjusting the toolpath for efficient and safe machining, improving cutting conditions and allowing higher machining speeds to be maintained.

Autodesk Inventor®, Solid Edge®, SolidWorks®, Pro/ENGINEER®, Pro/DESKTOP® Unigraphics files up to and including NX5, and CATIA V5.This means that you machine exactly what the designer intended and toolpaths remain associative to the master model. Unlike many CAM systems, EDGECAM is ‘CAD neutral’, so whatever CAD system you use, interoperability between CAD and CAM is seamless, with no data translation. With an extensive suite of advanced 3D cycles that are ideally suited for rapidly generating toolpaths for all surface and solids machining needs, EDGECAMs advanced machining cycles bring optimized toolpath control, reduced cycle times and an overall higher level of machining efficiency. EDGECAM offers not only best in class prismatic machining capabilities, you also have powerful 3D solid and surface machining strategies, all in one solution. Industries involved in the manufacturing of 3D forms such as Aerospace, Prototyping, Mold Tools and General Engineering will all benefit from EDGECAM’s 3D machining cycles. Efficient link moves for High Speed Machining.

#TROCHOIDAL MILLING PROGRAMMING UG NX DEMO FREE#

Though applied for different reasons on different machine types, all forms of compensation allow the CNC user to allow for unpredictable conditions related to tooling.EDGECAM 3D Milling Intelligent Machining From Native CAD DataĮDGECAM’s 3D capability offers a complete solution for generating high quality, gouge protected toolpaths that meet the demands of manufacturers tasked with the programming and machining of complex parts and free form shapesĮDGECAM offers not only best in class prismatic machining capabilities, you also have powerful 3D solid and surface machining strategies Features at a glance: Key CNC Concept #4-The Forms Of Compensation And yet the speed of production still can be increased. With titanium, in other words, there may be more than one reason why the cutting speed can’t be increased. Thanks to the metal’s low thermal conductivity, overly aggressive milling may even pose a risk of combustion. Milling titanium is different from other metals because of the risk of heat build-up.

#TROCHOIDAL MILLING PROGRAMMING UG NX DEMO HOW TO#

How to Choose the Right Tool for Milling Titanium This article explains why the centerless process works and how to use it most effectively in your shop. Most application problems associated with centerless grinding derive from a misunderstanding of the basics. Achieving consistent and quality results from the centerless grinding process requires an understanding of the basic fundamentals.

0 kommentar(er)

0 kommentar(er)